Ukuxilongwa Kwesimo Sedivayisi

Ukuqapha kanye nokuxilongwa yizindlela zobuchwepheshe eziyisisekelo zokuthuthukisa ukwethembeka kwemishini.Ngemishini yokuhlola echwepheshile, izimpawu zokuqala zokwehluleka zingatholwa futhi kusetshenzwe ngazo ngesikhathi.

I. Ukuqapha ukudlidliza nokuxilongwa kwephutha

Ochwepheshe abachwepheshile baphatha amathuluzi esizeni ukuze aqashwe ungaxhunyiwe ku-inthanethi, angahlinzeka ngokutholwa kwesimo kanye nezinsizakalo zokuxilongwa kwamaphutha ezinjini, amabhokisi egiya kanye nemishini ehlukahlukene yezimboni, abikezele amaphutha kubasebenzisi kusenesikhathi futhi athuthukise ukuthembeka kwemishini.

Ingakwazi ukubona ukuxilongwa kusenesikhathi kwamaphutha ahlukahlukene njengokuhlanganisa ukuhlanganisa, ibhalansi eguquguqukayo ye-rotor, ukuqapha isisekelo semishini, ukuqapha okuthwalayo, njll., futhi inikeze amakhasimende izisombululo.

II.Ukuqapha izimoto kanye nokuxilongwa kwephutha

Gada ukusebenza kwezinjini ezinamandla kagesi.Yenza igebe lomoya we-rotor kanye nokuhlaziywa kokuqina kazibuthe, ukuhlaziya ukufakwa kwe-insulation, ukuhlaziya iphutha ledivayisi yokuguqula imvamisa, ukuhlaziywa kwephutha kwesistimu yokulawula isivinini se-DC, ukuxilongwa kwemoto okuhambisanayo, i-DC motor armature kanye nokuxilongwa kokuvunguza kwe-excitation yamamotho e-AC.Ukuhlaziywa kwekhwalithi yokuphakelwa kwamandla.Ukutholwa kwezinga lokushisa kwezinjini, izintambo, amatheminali e-transformer, namatheminali ekhebula lamandla kagesi aphezulu.

III.Ukutholwa kwetheyiphu

Ukuhlola okwenziwa ngesandla akukwazi ukubona ukuthi intambo yensimbi ekutheyiphu iphukile, nokuthi intambo yensimbi ekuhlanganyeleni iyanyakaza yini.Kungahlulelwa kuphela ngokuzithoba ngezinga lokuguga kwenjoloba, okuletha izingozi ezinkulu ezifihliwe ekukhiqizeni okujwayelekile nokusebenza."I-Wire Tape Detection System", engakwazi ukubona ngokucacile futhi ngokunembile isimo sezintambo zensimbi namajoyinti kanye nezinye iziphambeko ku-tape.Ukuhlolwa ngezikhathi ezithile kwetheyiphu kungabikezela izimo zesevisi kanye nempilo ye-tape yokuphakamisa kusengaphambili, futhi kugweme ngokuphumelelayo ukuphuka kwentambo yensimbi.I-hoist yehlisiwe futhi itheyiphu yocingo lwensimbi yaphuka, okwaphazamisa kakhulu ukusebenza okuvamile kokukhiqiza.

IV.Ukuhlola okungonakali

Le nkampani inama-ultrasonic flaw detectors, ama-jitness gauge, ama-electromagnetic ejoka flaw detectors, kanye ne-magnetic flaw detectors.

V. Ukuhlolwa kwesisekelo

Ikakhulukazi senza izinsizakalo zokuhlola kanye nokwenza imephu ezifana nemephu yemephu yendawo, ukumepha imingcele yesokudla, ukuhlola, ukulawula, ukuhlola, ukuqapha ukuguquguquka, ukuqapha ukuhlaliswa, ukugcwalisa kanye nokuhlola ukumba, ukubalwa kokwakhiwa kobunjiniyela, ukwakhiwa kwendawo kanye nokuhlolwa kwezimayini, njll.

VI.Ukutholwa kwe-rotary kiln nokulungiswa

Sisebenzisa imishini ethuthukisiwe ukuqapha isimo se-rotary kiln.Ingakwazi ukubona ubuqotho be-axis emaphakathi yerola ngalinye elibambayo, isimo sokuthintana serola ngalinye elibambayo nerola, ukutholwa kwesimo samandla serola ngalinye elibambayo, ukutholwa kwe-ovality ye-rotary kiln, ukutholwa kwesiliphu serola. , ukutholwa kwerola kanye nekhanda lomlilo , ukulinganisa kokuphuma kwe-radial runout komsila we-kiln, ukuthintana kwe-roller ye-rotary kiln kanye nokutholwa kokuthambekela, ukutholwa kwegiya lendandatho enkulu yokuphuma kokuphuma nezinye izinto.Ngokuhlaziywa kwedatha, uhlelo lokwelapha lokugaya nokulungiswa luyakhiwa ukuze kuqinisekiswe ukuthi i-rotary kiln isebenza kahle.

VII.Ukulungiswa kwe-welding yokuqhekeka

Nikeza izinsiza zokulungisa nokulungisa ama-welding uma kunezinkinga emishinini yokufaka imishini, ukulingisa kanye nezingxenye zesakhiwo.

VIII.Ukulinganisa okushisayo

Ukuhlola okushisayo kanye nokuhlonza uhlelo lokukhiqiza usimende, ikakhulukazi ukuhlola okunemininingwane yonke ngezinjongo ezilandelayo, futhi uhlele imiphumela yokuhlolwa nezinhlelo zokwelashwa zibe umbiko osemthethweni futhi uwuthumele efekthri yekhasimende.

A. Okuqukethwe kwesevisi:

1) Ngokuya ngezidingo zomsebenzi wokonga amandla kanye nezimo ezithile zebhizinisi, khetha into yebhalansi eshisayo.

2) Ngokwenhloso yobunjiniyela obushisayo, nquma uhlelo lokuhlola, qala ngokukhetha indawo yokulinganisa, faka ithuluzi, yenza isibikezelo kanye nesilinganiso esisemthethweni.

3) Yenza izibalo ngazinye kudatha etholwe ekuhlolweni kwephuzu ngalinye, qedela ibhalansi yezinto ezibonakalayo nezibalo zebhalansi yokushisa, futhi uhlanganise ithebula lebhalansi yezinto ezibonakalayo kanye nethebula lebhalansi yokushisa.

4) Ukubalwa kanye nokuhlaziywa okuphelele kwezinkomba ezihlukahlukene zobuchwepheshe nezomnotho.

B. Umthelela wesevisi:

1) Kuhlanganiswe nezimo zokusebenza zefekthri, imingcele yokusebenza ithuthukiswa ngokulingisa izinombolo zeCFD.

2) Thuthukisa izinhlelo zokulungisa ezichwepheshile zezinkinga zebhodlela ezithinta ukukhiqiza ukusiza amafekthri ukuthi afeze ukusebenza kwekhwalithi ephezulu, okunesivuno esikhulu, nokusetshenziswa kancane.

Isistimu yokucindezela inkungu eyomile

Eminyakeni yamuva nje, ngokufudumala kwemakethe yemboni kasimende kanye nokuthuthukiswa kancane kancane kwezidingo zokuvikelwa kwemvelo kazwelonke, amabhizinisi ahlukahlukene kasimende agxile kakhulu empilweni yemvelo.Izinkampani zikasimende eziningi zenze isiqubulo sokwakha "imboni kasimende esengadini", kanti nokutshalwa kwezimali ekuguqulweni kwemvelo kuyakhula.

Indawo enothuli kakhulu yemboni kasimende igceke le-limestone.Ngenxa yebanga eliphakeme phakathi kwengalo ende ye-stacker kanye nomhlabathi, kanye nokungakwazi ukufaka umqoqi wothuli, isitaki siphakamisa umlotha kalula ngesikhathi senqubo yokupakisha, okuyinto engathandeki kakhulu empilweni yabasebenzi kanye nokusebenza kahle kwemishini. .

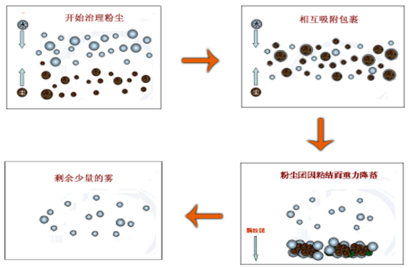

Ukuze ixazulule le nkinga, i-Tianjin Fiars intelligent technology Co, Ltd, yathuthukisa uhlelo lokucindezela uthuli oluyinkungu elomile.Umgomo wawo uwukukhiqiza inani elikhulu lenkungu eyomile ngombhobho we-atomizing, bese ufafaza ukuvala indawo lapho uthuli lukhiqizwa khona.Lapho izinhlayiya zothuli zithintana nenkungu eyomile, zizonamathela zodwa, zihlangane futhi zande, futhi ekugcineni zicwile ngaphansi kwamandla adonsela phansi azo ukuze kuzuzwe injongo yokuqeda uthuli.

Uhlelo lokucindezela uthuli lunezinhlelo zokusebenza ezine ezilandelayo:

I. Kufakwe kusitaki kanye nesitholi kabusha

Ukucindezelwa kwenkungu nothuli okomile ukufaka inombolo ethile yemibhobho engalweni ende yesitaki.Inkungu eyomile ekhiqizwa ama-nozzles ingavala ngokuphelele indawo engenalutho, ukuze uthuli lungakwazi ukuphakanyiswa, ngaleyo ndlela ixazulule ngokuphelele inkinga yegceke.Inkinga yothuli ayiqinisekisi kuphela impilo yabasebenzi beposi, kodwa futhi yandisa impilo yesevisi yemishini kanye nezingxenye ezisele.

II.Ifakwe ophahleni lwegceke lokugcina impahla eluhlaza

Egcekeni lempahla eluhlaza elingasebenzisi isitokisi ukuze lithulule, inani elithile lemibhobho lingafakwa phezu kophahla, futhi inkungu ekhiqizwe imibhobho ingacindezela uthuli oluphakanyiswe emoyeni.

III.Kufakwe ezinhlangothini zombili zomgwaqo

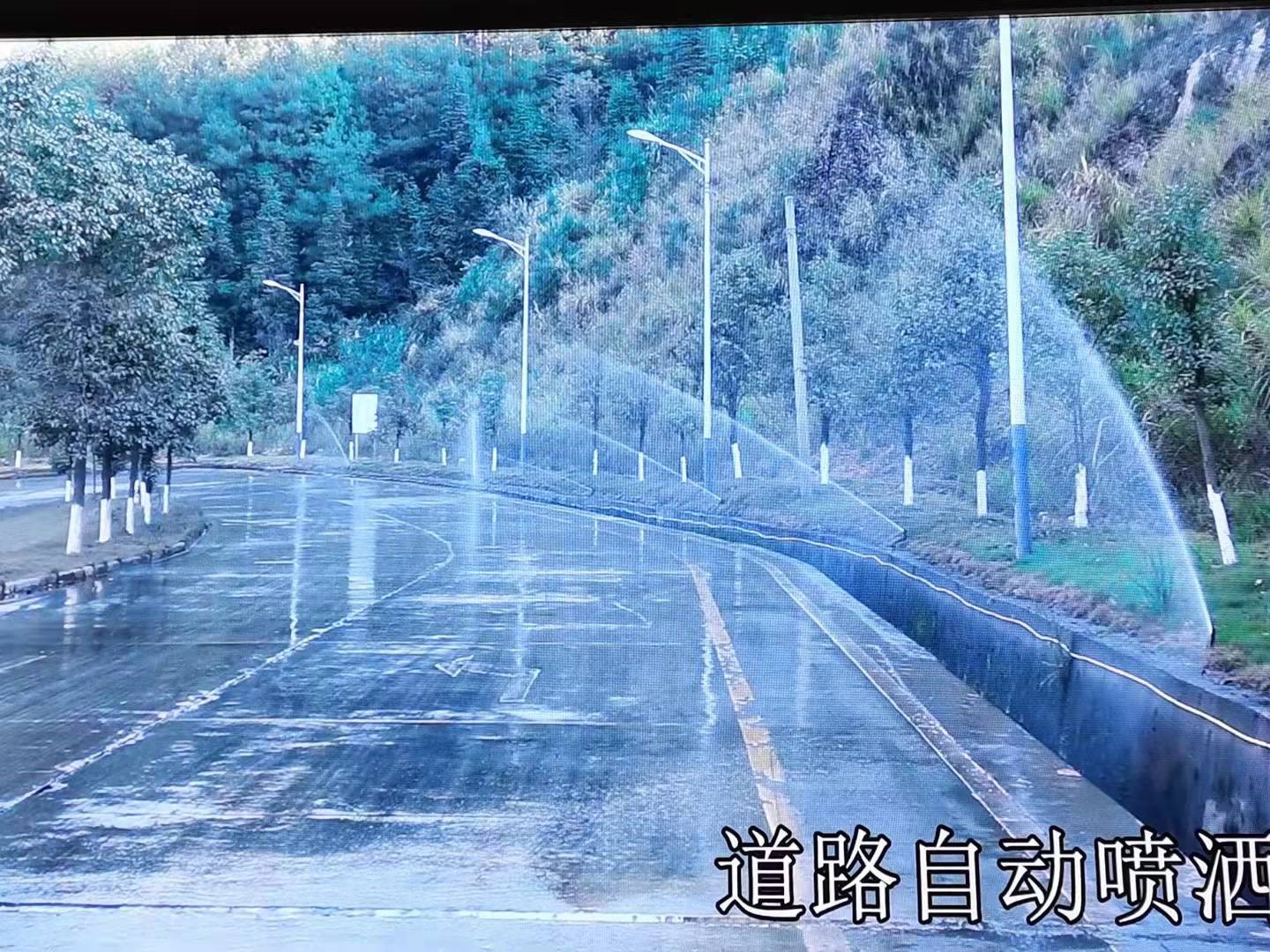

Isistimu yokucindezela uthuli lwe-spray ingasetshenziselwa ukufafaza komgwaqo okuzenzakalelayo, okungacindezela uthuli futhi kuvimbele ama-catkins nama-poplars akhiqizwa entwasahlobo.Ukufafaza okuqhubekayo noma ngezikhathi ezithile kungasethwa ngokuvumelana nesimo.

IV.Okokufutha ngemishini

Isistimu yokucindezela uthuli lwesifutho nayo ingasetshenziselwa ukufafaza imishini.Izisetshenziswa eziphezulu noma izinga lokushisa lesistimu elibangelwa izinkinga zenqubo noma zemishini kuzothinta ukuphepha kwemishini, isikhathi kanye nekhwalithi yomkhiqizo.Ngokwesimo sangempela, uhlelo lwe-spray (amanzi) lungafakwa endaweni lapho izinga lokushisa eliphezulu likhiqizwa khona, futhi idivayisi yokulungiswa okuzenzakalelayo ingacushwa, engakwazi ukuqala ngokuzenzakalelayo futhi ime ngokuhambisana nebanga lokushisa elibekiwe ngaphandle kokusebenza ngesandla.

Uhlelo lokucindezela uthuli lwenkungu elomile olwakhiwe yi-Tianjin Fiars luwuhlelo oluvuthiwe noluthembekile.Ixazulule inkinga yomlotha osindayo ezitshalweni zikasimende ezingaphezu kuka-20 njenge-BBMG neNanfang Cement, futhi iye yamukelwa kahle amakhasimende ethu.